A New Boost for Steel-Free Solutions

In recent years, the search for sustainable alternatives to steel has gained momentum in the construction industry. Composite rebar, made from materials such as glass fiber or carbon fiber, is emerging as a modern, lightweight, and corrosion-resistant solution, ideal for demanding environments and long-lasting structures.

In this context, various European organizations are actively collaborating to consolidate the use of non-metallic structural reinforcement, marking a transition toward more efficient and future-ready infrastructure.

What Is Composite Rebar and Why Is It Gaining Ground?

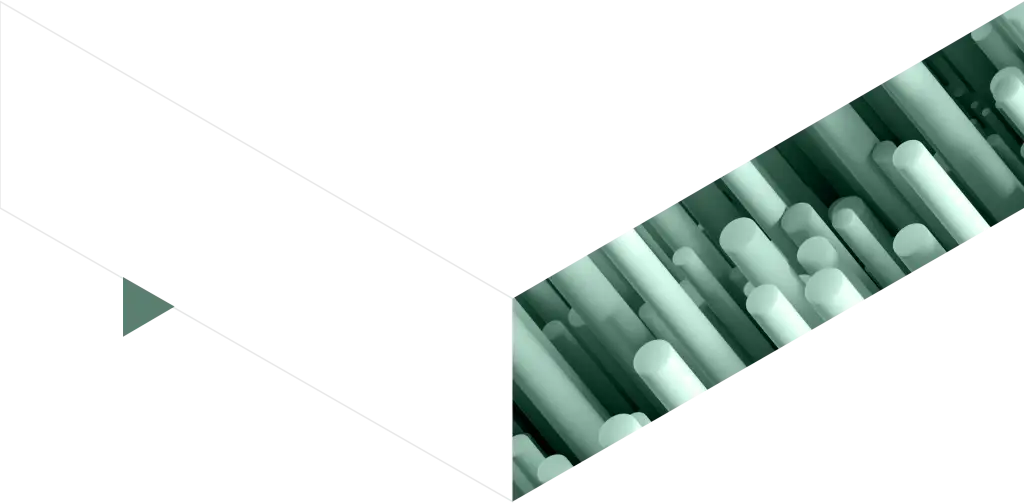

The term rebar refers to reinforcement bars used in concrete structures. Historically, they have been manufactured from steel. However, thanks to advances in composite materials, reinforced polymer versions are now available, known as GFRP (Glass Fiber Reinforced Polymer) or CFRP (Carbon Fiber Reinforced Polymer) bars.

These bars stand out for:

• Not corroding in humid or saline environments

• Being significantly lighter than steel

• Maintaining stable mechanical properties over time

• Allowing faster and safer installation

In bridge, tunnel, port, and water-exposed structures, the use of composite rebar offers key advantages in terms of durability and sustainability.

Europe Moves Toward Standardization of Composite Rebar

As the composite reinforcement bar market grows, so does the need for common standards and certification systems. Different industry alliances, supported by entities such as EuCIA, are developing technical frameworks to ensure the quality, safety, and reliability of these materials.

The creation of specialized working groups focused on certification, promotion, and public policy reflects a clear commitment from the European sector: to provide viable alternatives to steel in the construction projects of the future.

The Challenge: Educating the Market and Demonstrating the Benefits

One of the main challenges to the widespread adoption of non-metallic rebar is the lack of technical knowledge among designers, engineers, and public administrations. Training initiatives and the dissemination of real success stories are essential for building confidence and momentum in both public and private projects.

At Polymec, as manufacturers of technical composite profiles, we closely follow these initiatives, convinced of the value that pultruded materials bring to environments where corrosion or exposure to aggressive agents is a constant factor.

What Can Polymec Contribute to the Development of Composite Rebar?

Although our primary focus is the manufacture of glass fiber-reinforced polyester structural profiles, at Polymec we have the technical expertise and pultrusion process experience required to develop customized reinforcement bars tailored to the specific needs of each project.

We are committed to innovative solutions that combine mechanical performance, durability, and ease of installation. Our team is ready to collaborate with engineering firms, construction companies, and public entities interested in incorporating corrosion-free alternatives into their structures.

Toward Lighter, Safer, and Maintenance-Free Construction

The use of composite reinforcement bars is not a passing trend. It is a real technical response to the current challenges of the sector: more durable structures, more sustainable construction, and solutions that reduce long-term maintenance costs.

Polymec firmly believes that the future of structural reinforcement lies in composites. We will continue to closely monitor the work of European alliances, with the aim of contributing our expertise to the development of more innovative, efficient, and long-lasting construction.